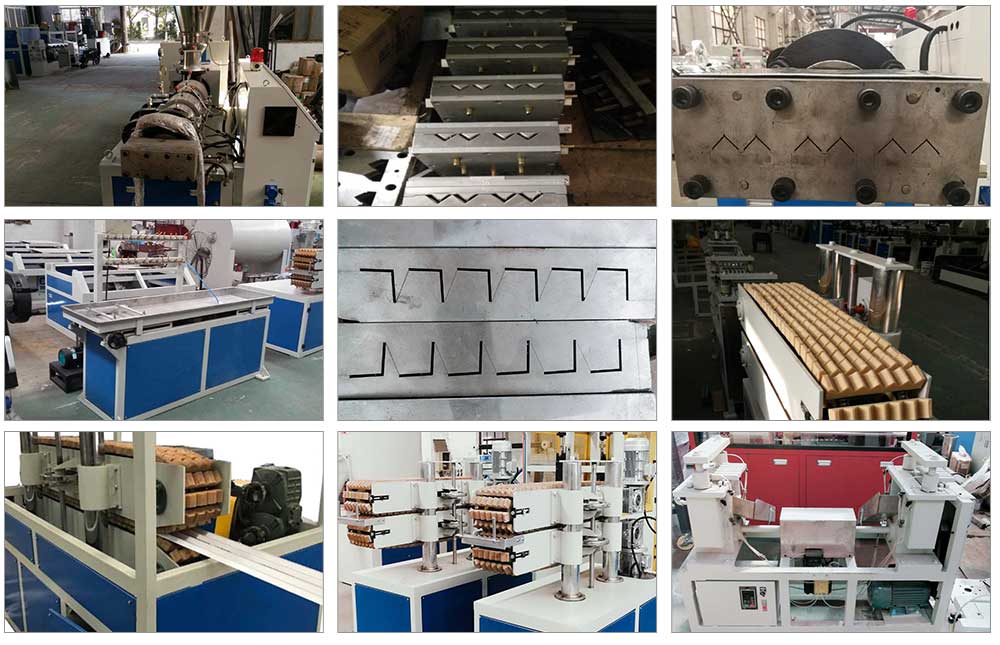

PVC Corner Extrusion Line

1. The PVC Corner extrusion line has been improved from the original One-out-of-Two to One-out-of-Four & One-out-of-Six extrusion line, which increases capacity but reduces labor costs;

2. The old-fashioned punching machine of PVC Corner extrusion line has been improved to high-speed punching machine (easy to operate). Products are not easy to break during the production process, and processing is stable and more power-saving;

3. PVC corner production line consists of twin-screw (or single-screw) extruders, customized moulds, vacuum stereotype table, specialized hauling-off machine, high-speed punching machine, and automatic stacking machine (new type of machine).

2. The old-fashioned punching machine of PVC Corner extrusion line has been improved to high-speed punching machine (easy to operate). Products are not easy to break during the production process, and processing is stable and more power-saving;

3. PVC corner production line consists of twin-screw (or single-screw) extruders, customized moulds, vacuum stereotype table, specialized hauling-off machine, high-speed punching machine, and automatic stacking machine (new type of machine).

Layout:

Production Process Raw Material + Additive Preparation (Formula) → Mixing ( Mixer Unit) → Loading (Screw Loader) → Conical Twin-Screw Extruder → Customized Mould → Vacuum Stereotype Table → Specialized Hauling-off Machine → Punching Machine → Automatic Stacking Machine (PLC control)

| Model | One-Out-of-Four | One-Out-of-Six |

| Screw Diameter /mm | 55/113 | 65/132 |

| Extruder Motor / kw | 22 | 37 |

| Screw Speed /r.min | 1-37 | 1-34.7 |

| Capacity / kg.h | 100-150 | 180-250 |

| Hauling Effective Length / mm | 1800 | 1800mm |

| Automatic Stacking Machine | PLC Control + Touch Screen | PLC Control + Touch Screen |

The automatic stacking machine is a fully automatic intelligent device specially designed for the construction of PVC Corners extrusion line. It can automatically code the number according to the users’ needs – with a certain method and quantity. It is convenient for packing and has the characteristics of accurate stacking, accurate counting and saving time & labors.