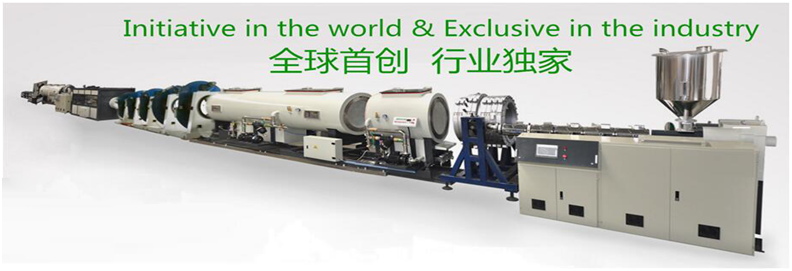

CFRTP Pipe Extrusion Line

Pipe Diameter Range: Φ80 – Φ500

The emerging reinforced material – Composite Fiber Thermoplastic Reinforced Pipe (CFRTP), has brought new opportunities to the plastic pipe industry. CFRTP production line is to use the principle of pre-impregnated glass ribbon to increase the strength of the product. It is a more direct and effective new method which can greatly increase the pressure resistance and reduce the cost.

1. Beautiful appearance and strong internal;

2. Main machine adopts the most advanced high-speed efficient screw, European technology high-torque gearbox, high energy saving long life heater, non-contact solid state relays, high strength metal coating and memory powerful Siemens PLC software;

3. Vacuum calibration tank adopts a system which can control water level and water temperature automatically; Pipeline has used European-style oversized water filter to ensure that the pipeline will keep unblocked for a long time;

4. Haul off adopts multi-power constant torque servo motor traction, multi-track with the same into the same, not only increase the traction torque, but also ensure the roundness of the pipe;

5. Pipe cutter adopts No-Dust cutting technology, which can work silent and no dust is produced. It also can ensure the incision smooth and neat.

Layout:

Inner Extruder → Inner Mould → Inner Vacuum Calibration Tank → Fiberglass Winding Machine → Outer Extruder → Outer Mould → Spray Cooling Tank → Front Hauling-Off → Rotary Tempering Box → Outer Vacuum Calibration Tank → Rear Hauling-Off → Fixed Length Chipless Cutter → Stacker

![]()

| Models | CFRTP150、CFRTP350、CFRTP500 |

| Production Line Speed & Size range | CFRTP150 ≤0.65m/min ¢80、¢100、¢125、¢150 |

| CFRTP350 ≤0.55m/min ¢200、¢250、¢300、¢350 | |

| CFRTP500 ≤0.45m/min ¢400、¢450、¢500 | |

| Over 500 to be advised |